Quality & Support

Home > Quality & Support

Quality Assurance

We Have Come A Long Way

8 Stage Advanced Quality Check

Neelkanth Cables Ltd has developed a strict 8-STAGE quality control testing procedure which ensures our cables are among the best found anywhere in the world.

STAGE 1

COPPER ROD MANUFACTURING

In house Cu rod manufacture High Conductivity 102% High Ductility Purity 99.99%

STAGE 2

PVC COMPOUND MANUFACTURING

In house PVC Manufacture Insulation Resistance, Thermal stability Virgin PVC and no recycle PVC

STAGE 3

OTHER INPUT RAW MATERIALS

Electrical/Mechanical and Physical properties as per related Standards

STAGE 4

CONDUCTOR MAKING

In house conductor resistance checking Ductility

STAGE 5

INSULATION EXTRUSION PROCESS

Insulation Resistance and Thickness Inline Insulation “Measurement and Control” through complete length

STAGE 6

CABLE BUILT UP PROCESS

In process Quality “Measurement and Control” as per relevant Standards

STAGE 7

FINISHED GOODS TESTING

Type and Routine Tests Acceptance Test as required

STAGE 8

PACKAGING & STORAGE

In house Drum making Steel & Wood As per MSDS Norms

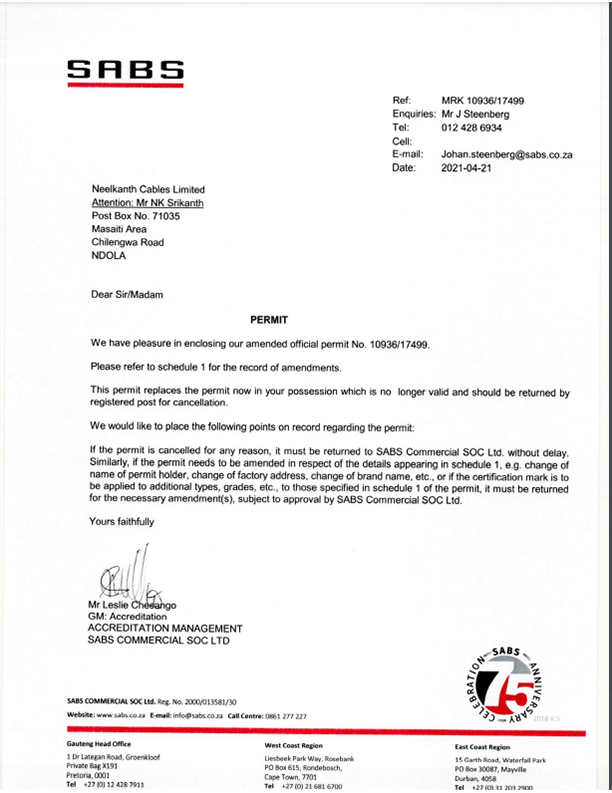

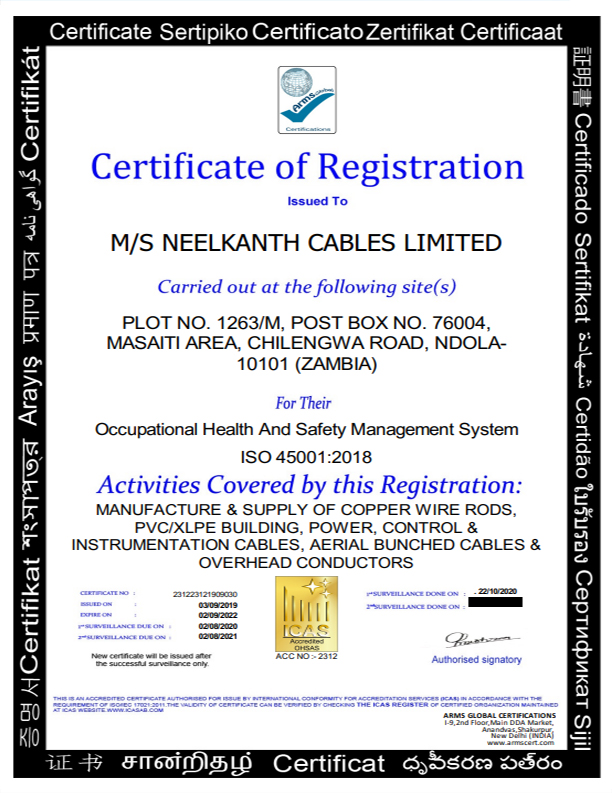

System certification

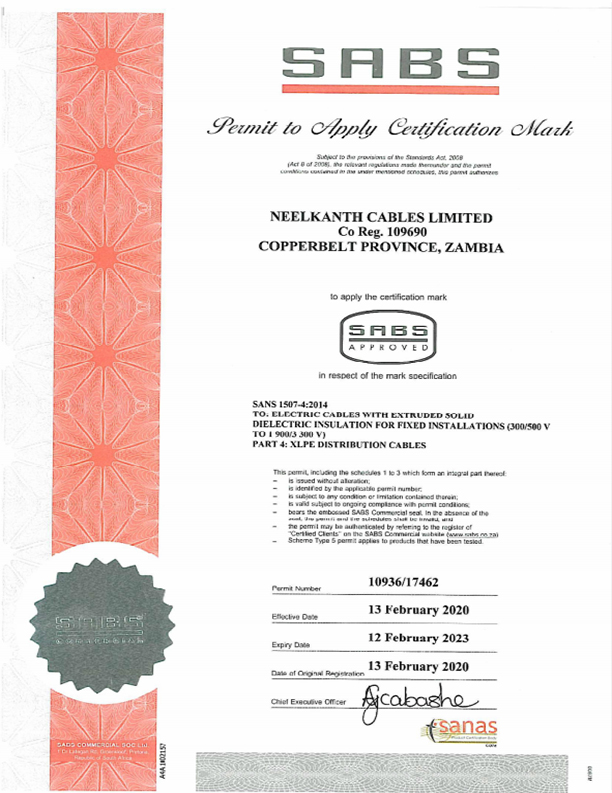

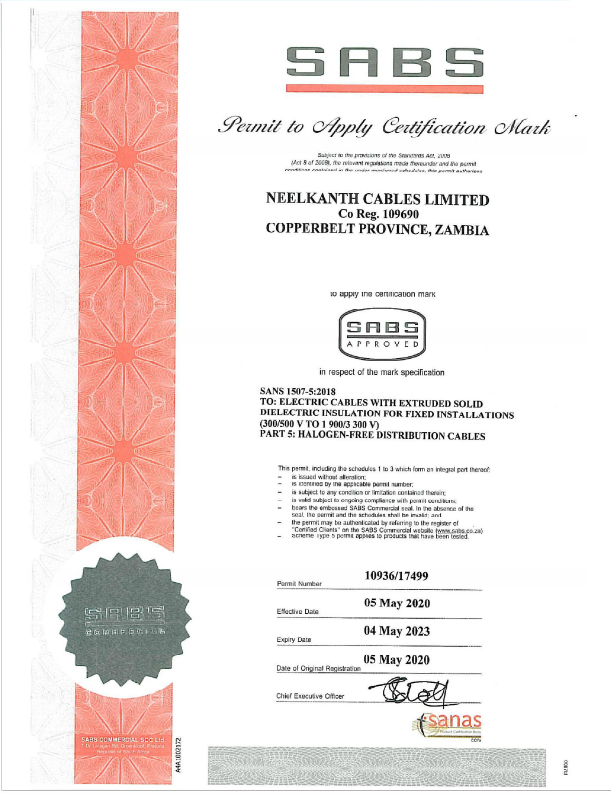

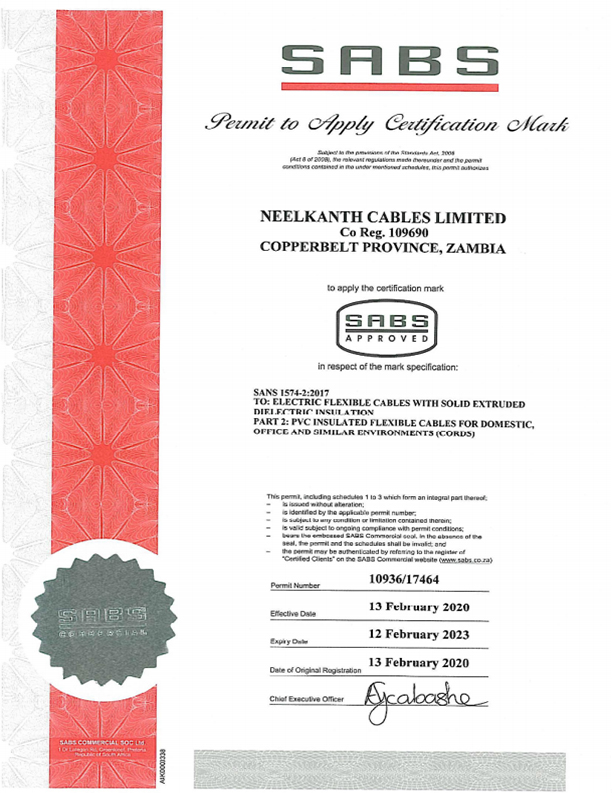

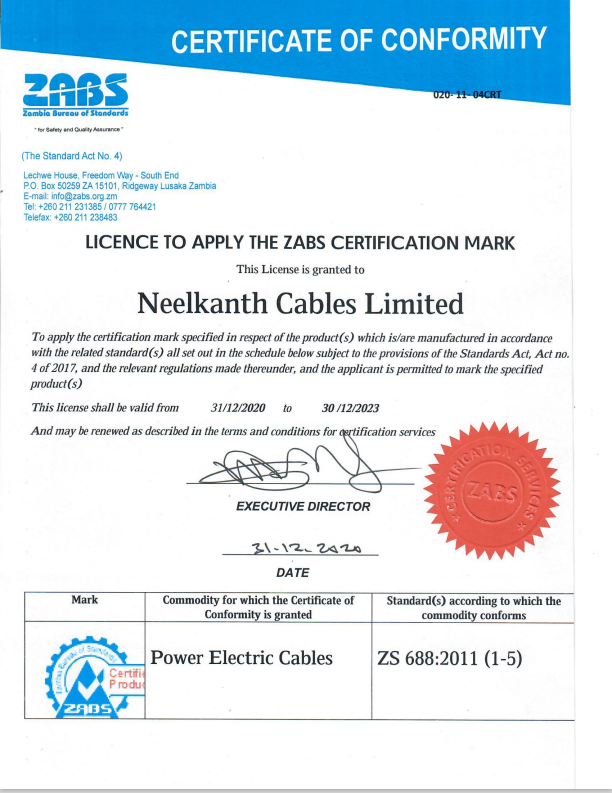

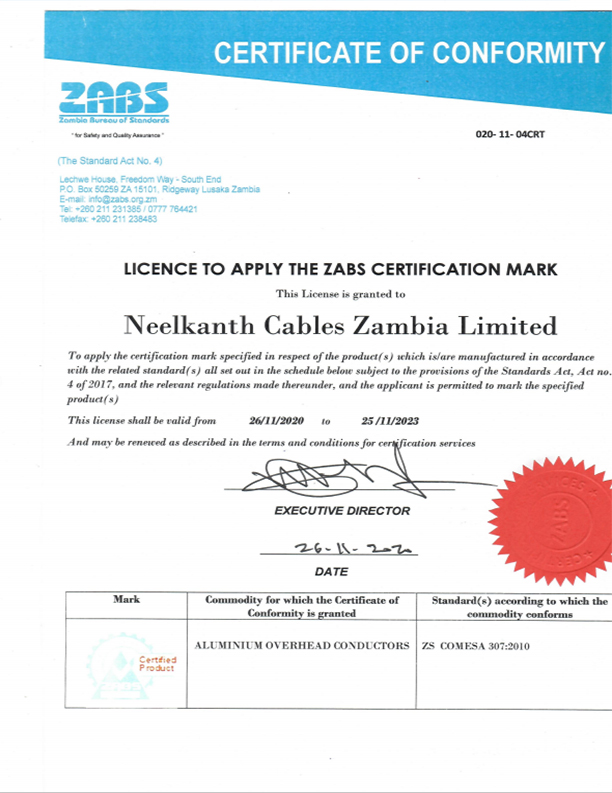

Product certification

Creating Difference With Assistance And Beyond

Technical Service and Support

At Neelkanth Cables the technical support team does not stop at just creating the successful design and production of the cable. In addition to all the services, a comprehensive cable advisory service is also offered. Technical staff are available to assist and provide expert solutions to all types of cable issues and requirements.